About Us

Professional Micro Fluid Control Expert

Jtseiko Best Valve supplier That You Can Trust

Over hundreds of types for selection of Valve!

Bio-compatible, Food Grade, Rohs, Reach, Pahs Certifications for Material.

Material Selection of Chemical,Oil,Medicine,Acid,Alkaline,Ozone, Gas Resistent.

Air & Liquid flow test data. Aging, lifetime, chemical resistent test data by JTSEIKO’s Lab.

With designers, engineers, mould workshop to provide OEM & ODM service.

100% Production Inspection, 0 complains with millions of valve using.

Our Advantage

R&D and Innovation

Mold Making

Strict Quality Control

Product Design

Efficient Production

Our Manufacturing Philosophy

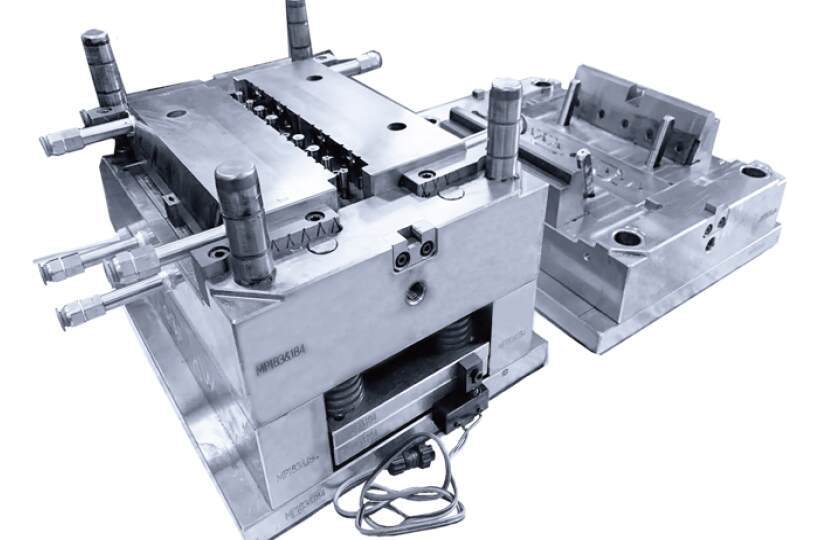

High-quality raw materials, precise molds, professional production equipment and production technology are the key to transform good design into high-performance products, which is the philosophy we always adhere to.

In order to provide consistent and reliable products and services, ISO9001 is the principle we always follow in the company’s operation and management. All products will be 100% inspected before delivery to customers, to ensure the best use of customers.

The high quality,

The raw materials

Precision mold

Reliable workmanship

Professional

production equipment

ISO9001

management system

Excellent idea

Factory qualification

ISO9001:2015

Patents

Patents

Patents

Why Choose Us

OEM & ODM project

Our service includes design, research & innovation, mould process, lab test, mass production and quality control etc.

Product Design

1, Professional designer for ODM work with 20 years' experience.

2, Review with customers together to meet market's request.

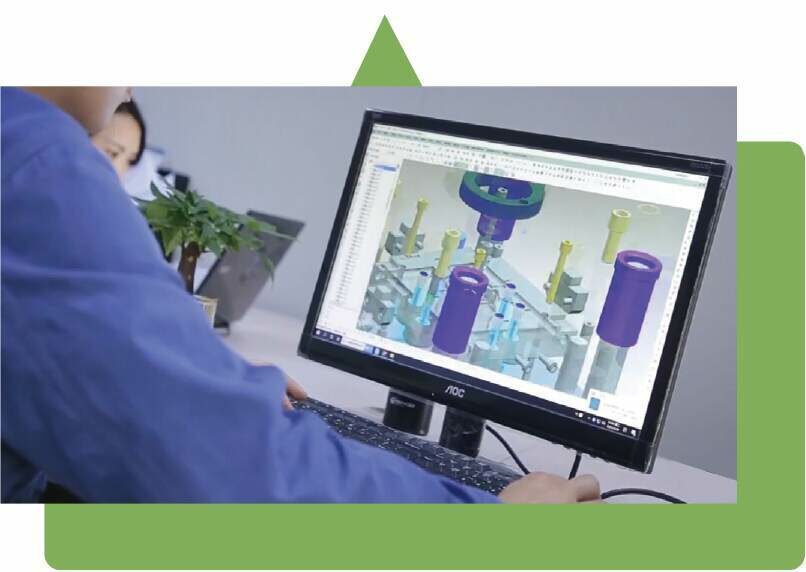

Mould & Product Process

1, CNC, Sodick EMD Machine, CMM of Serein to gurantee mould size.

2, Mould review with customer's engineer together to make sure details.

Labratory & Quality Control

1, Quality control by ISO9001 standards with first article inspection, patrol inspection every 2 hours, OQC, IQC, PPAP standards etc.

2, Lab test includes air/water flow, aging, chemical/UV/high & low tempreture resistent, vibration, tensile, etc.

Mass Production

1, 100% test for every product.

2, Automatic assembling and testing is widely used.

Product market and application

①Medical

Xian Medical’s clean production environment and strict quality control system ensure the health and safety of mass production of medical components.

②Smart Appliances

From coffee machines to sweeping robots, from washing machines, air conditioners to smart toilets, all have the wisdom and contributions of the Rubbe valve team.

③Small Engine

As the components of choice for industry customers Rubbervalve provides reliable components for millions of small engines and garden tools every year.

④Automobile

More efficient, safer, more comfortable, and more environmentally friendly are the goals that the automotive industry is constantly pursuing. Our newly developed materials can meet more stringent requirements, such as ethanol fuel, high temperature, and more environmentally friendly emissions.

⑤Health and Eoo Friendly

From air purification to water purification, from inductive hand washing to domestic sewage discharge. Rubbervalve one-way valve fully guarantees consumers a good product experience.

⑥Agricultural Irrigation

Precise micro-spray and drip irrigation are already the trend of agricultural irrigation. Rubbervalve’s precise micro-fluid control makes the majority of planting users feel the superiority of the technology.

R&D and Innovation

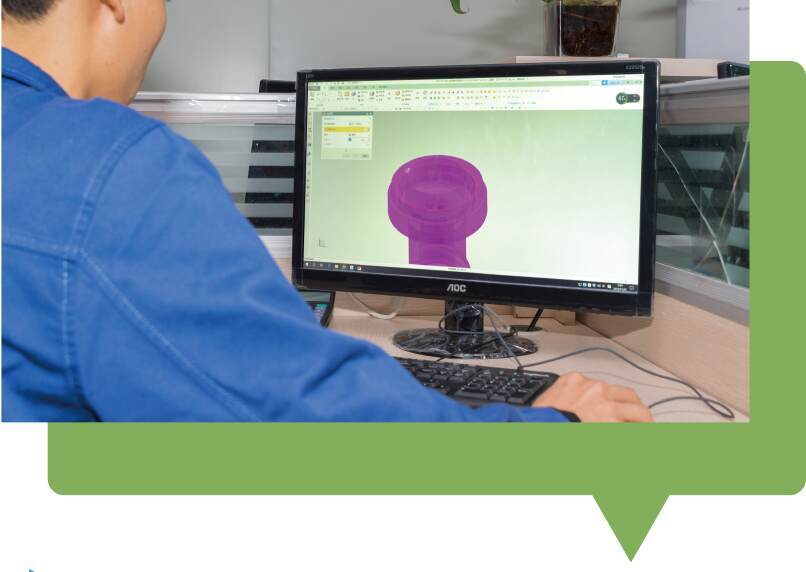

Product Design

Product Design

Experienced Design Team

Mold Design

Mold Design

mold making

EMD machine

CMM

High-Speed Processing Center

Mould

Mould Workshop

Inquiry Now

Make An appointment

Respond Time ≤24hours!

Online Meeting Appointment

Valve Selecting Suggest

Urgent Contact

Contact Information

+86 183 5916 3977

70# Rujiang Road, Mawei District, Fuzhou, China

Production

Professional production equipment and high-quality employees are important conditions for efficient and orderly production of enterprises. The company actively promotes the standardization of 5S management, scientific and orderly work Operation process, efficient and safe production mode and 10,000-class & 100,000-class purification workshops.

Injection Production

Manual Assembly Line

Rubber Valve Production

Auto-Assembly Machine

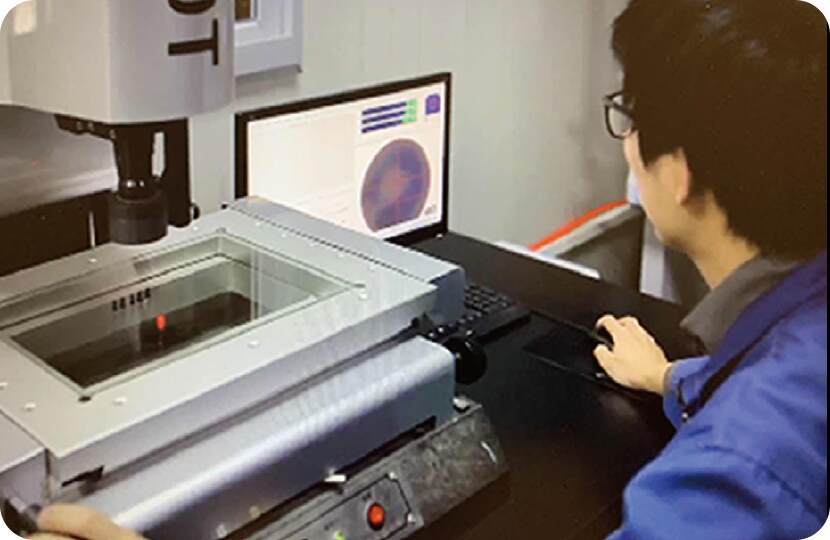

quality control

Professional testing equipment and perfect quality control system are the source of good quality.

Laboratory Overview

JTSeiko can carry out comprehensive performance tests on rubber and plastic materials to meet the technical needs of customers. Test items include rubber vulcanization curve, volume expansion rate, hardness Low Vibration, fatigue resistance, tension, high and low temperature, gas/liquid flow, spring rebound value, opening pressure, etc.

2D Projection