O Ring & Gasket

① Million times of lifetime

② Chemical Resistent by Different Material Solution.

③ Rohs, Reach Material Report.

Best Valve supplier That You Can Trust

Over hundreds of types for selection of Valve!

Bio-compatible, Food Grade, Rohs, Reach, Pahs Certifications for Material. Material Selection of Chemical,Oil,Medicine,Acid,Alkaline,Ozone, Gas Resistent. Air & Liquid flow test data. Aging, lifetime, chemical resistent test data by JTSEIKO’s Lab.

With designers, engineers, mould workshop to provide OEM & ODM service. 100% Production Inspection, 0 complains with millions of valve using.

Product introduction and features

Model

picture

specification

size

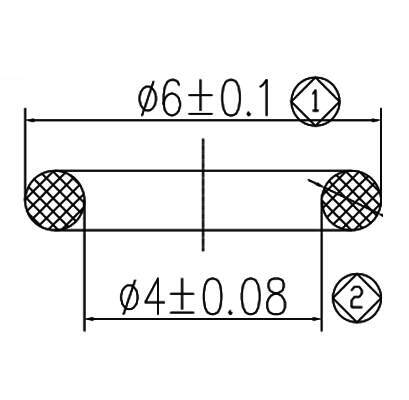

JT1148

ID: 4mm

OD: 6mm

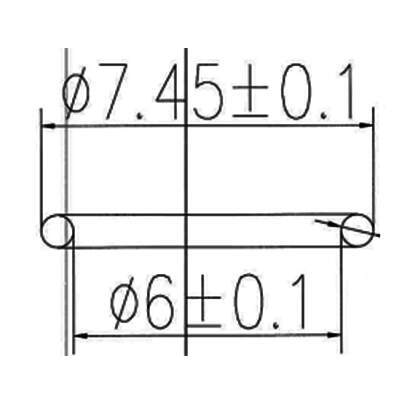

JT1248

ID: 6mm

OD: 7.4mm

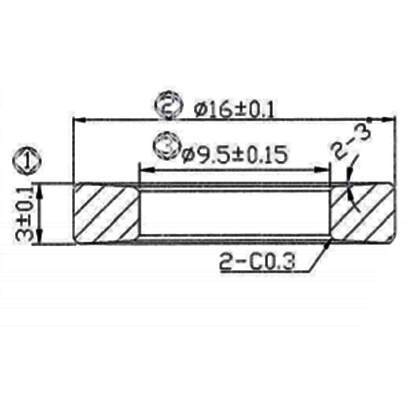

JT1264

ID: 9.5mm

OD:16mm

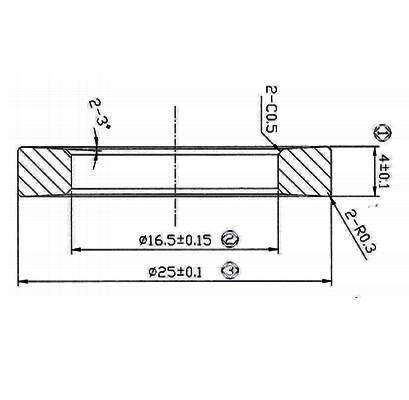

JT1265

ID: 16.5mm

OD:25mm

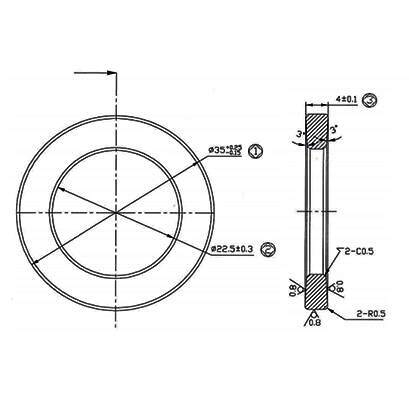

JT1279

ID: 226.5mm

OD:35mm

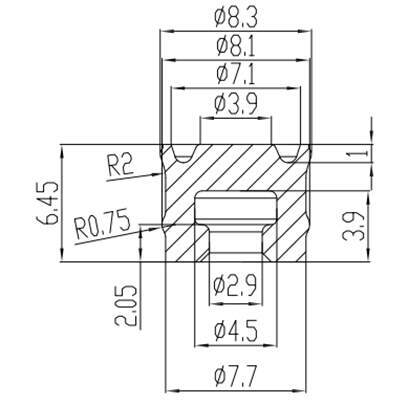

JT1234

ID:2.9mm

OD:8.3mm

Note:OEM & ODM services provided.

Why Choose Us

OEM & ODM project

Donec efficitur, enim bibendum volutpat dictum, tellus risus porttitor leo, eget ele ifend enim metus eu sem. Ut ipsum eros, bibendum et ligula vitae, sollicitudin.

Product Design

Donec efficitur, enim bibendum volut pat dictum, tellus risus porttitor leo, eget ele ifend enim metus eu sem. Ut ipsum eros.

Mould & Product Process

Donec efficitur, enim bibendum volut pat dictum, tellus risus porttitor leo, eget ele ifend enim metus eu sem. Ut ipsum eros.

Labratory & Quality Control

Donec efficitur, enim bibendum volut pat dictum, tellus risus porttitor leo, eget ele ifend enim metus eu sem. Ut ipsum eros.

Mass Production

Donec efficitur, enim bibendum volut pat dictum, tellus risus porttitor leo, eget ele ifend enim metus eu sem. Ut ipsum eros.

Selection of rubber materials

Item

Rubber Material Specification

Silicone

1. Tempreture Endurance: -50°C to 200°C.

2. Non toxic and environmentally friendly.

3. Low mechanical strength and chemicals.

FKM

1. Temperature Endurance: 200°C.

2. Chemicals resistant: compatible to most of media such as oil , acid with well performance.

3. Poor on Low temperature: under -0°C cause disfunctiona.

FVMQ

1. Temperature Endurance: -30°C to 150°C.

2. Chemicals resistant: compatible to most of media such as oil , acid with well performance.

3. Poor on mechnical performance.

NBR

1. Temperature Endurance: -10°C to 100°C.

2. Chemicals resistant: compatible to most of media such as oil , acid.

3. Poor on Low temperature: under -0°C cause disfunctional.

4. Economic Price.

EPDM

1. Temperature Endurance: -10°C to 120°C.

2. Chemicals resistant: Ozone resistance, ultraviolet resistance, weather resistance and aging resistance etc.

3. Poor on mechanical performance.

Note: Contact our engineer to learn more about materials’ info, such as NR, CR, ACM, etc.

Plant environment