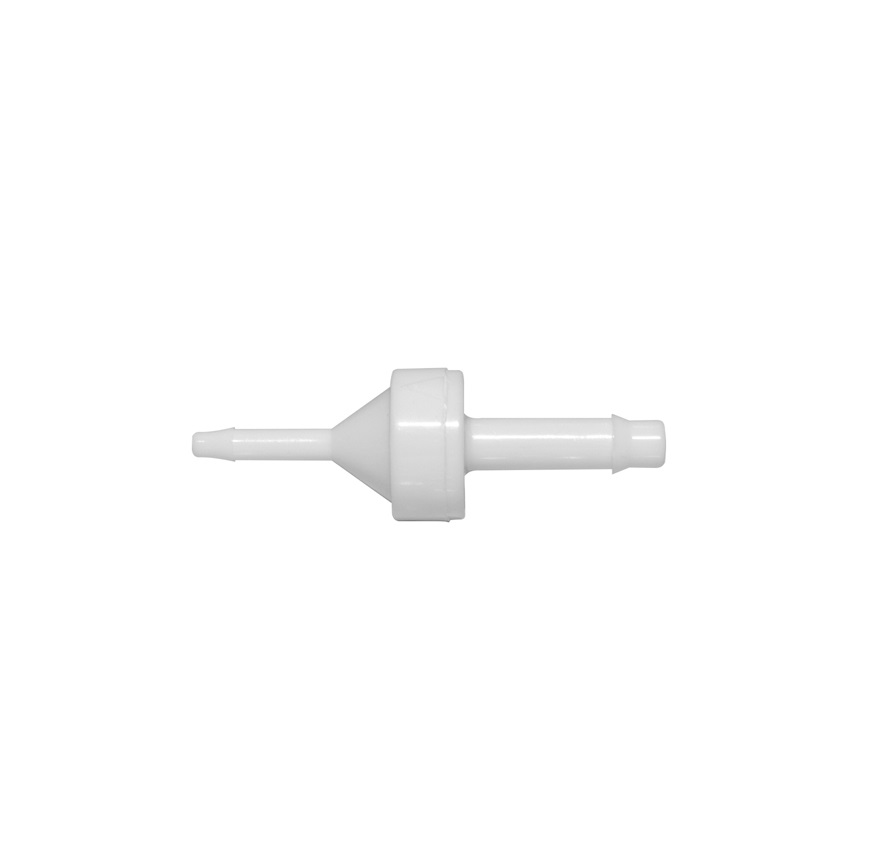

Check Valve

- Fuzhou, China

Rubber & Plastic Valve Manufacturer

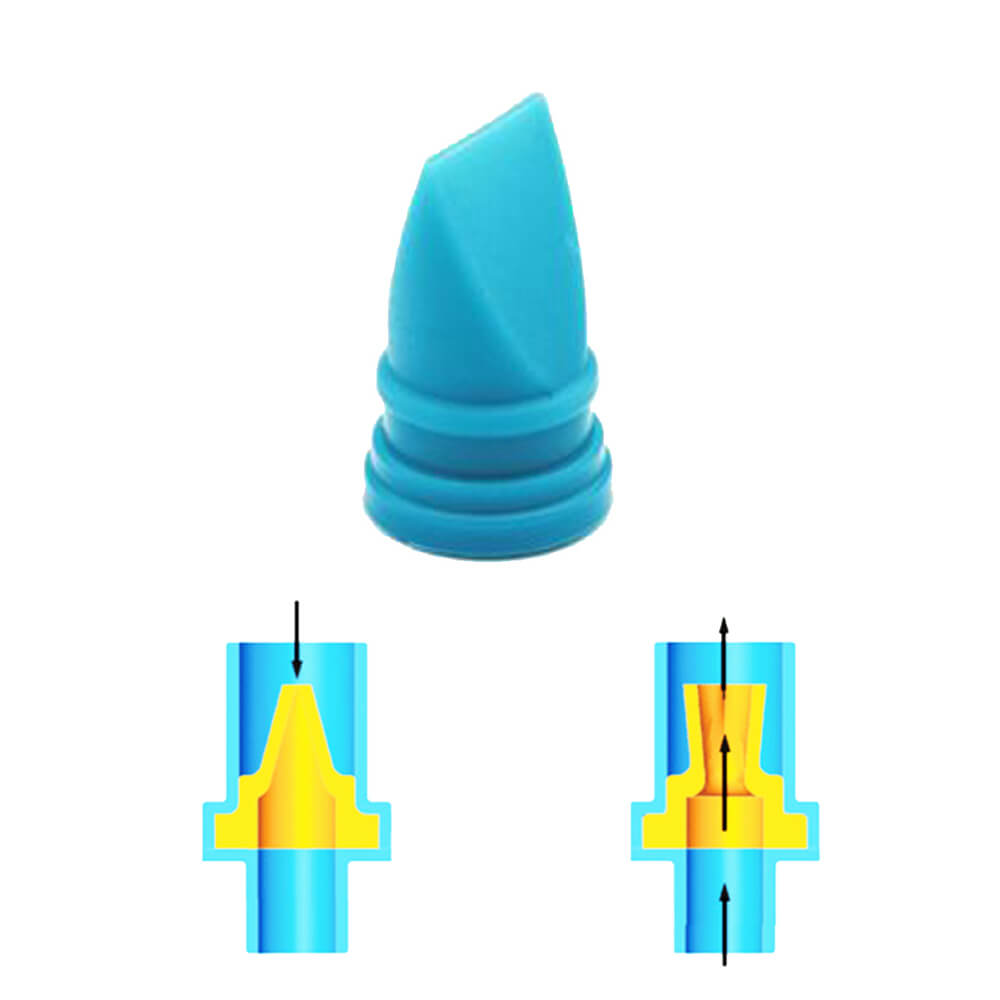

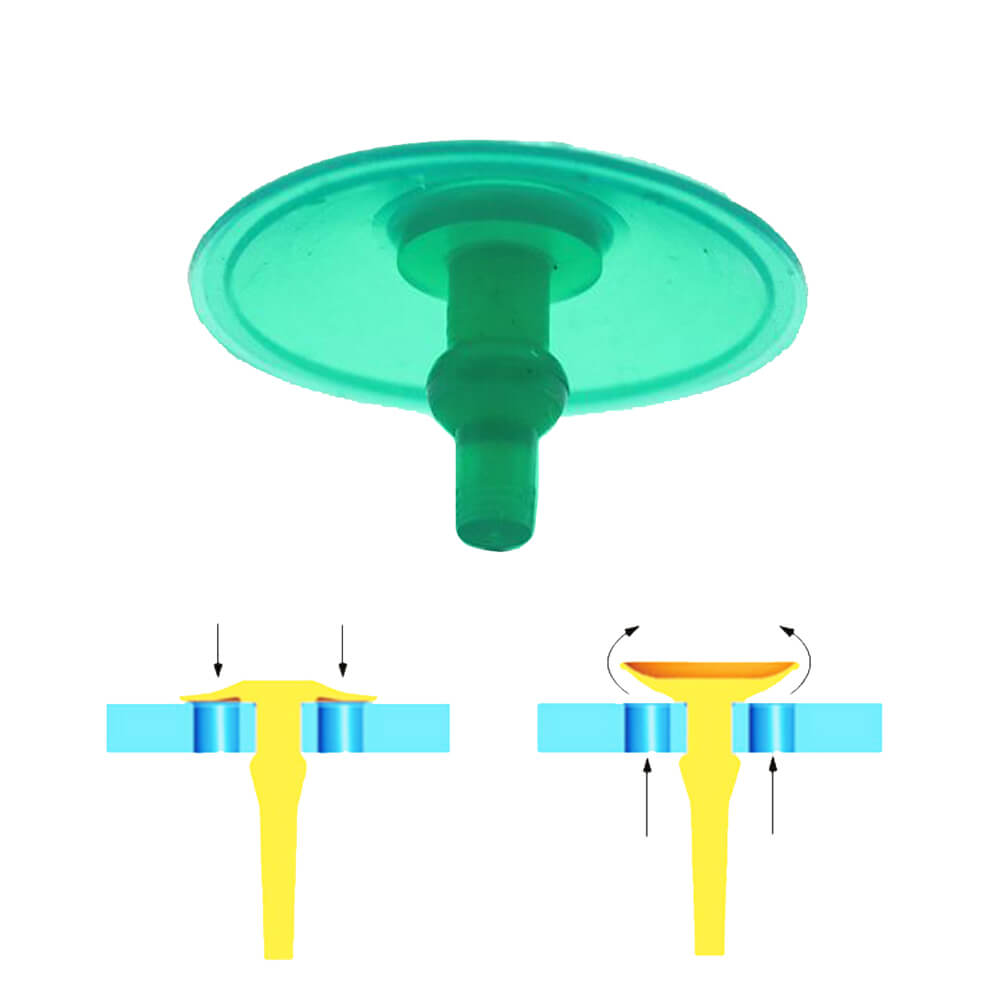

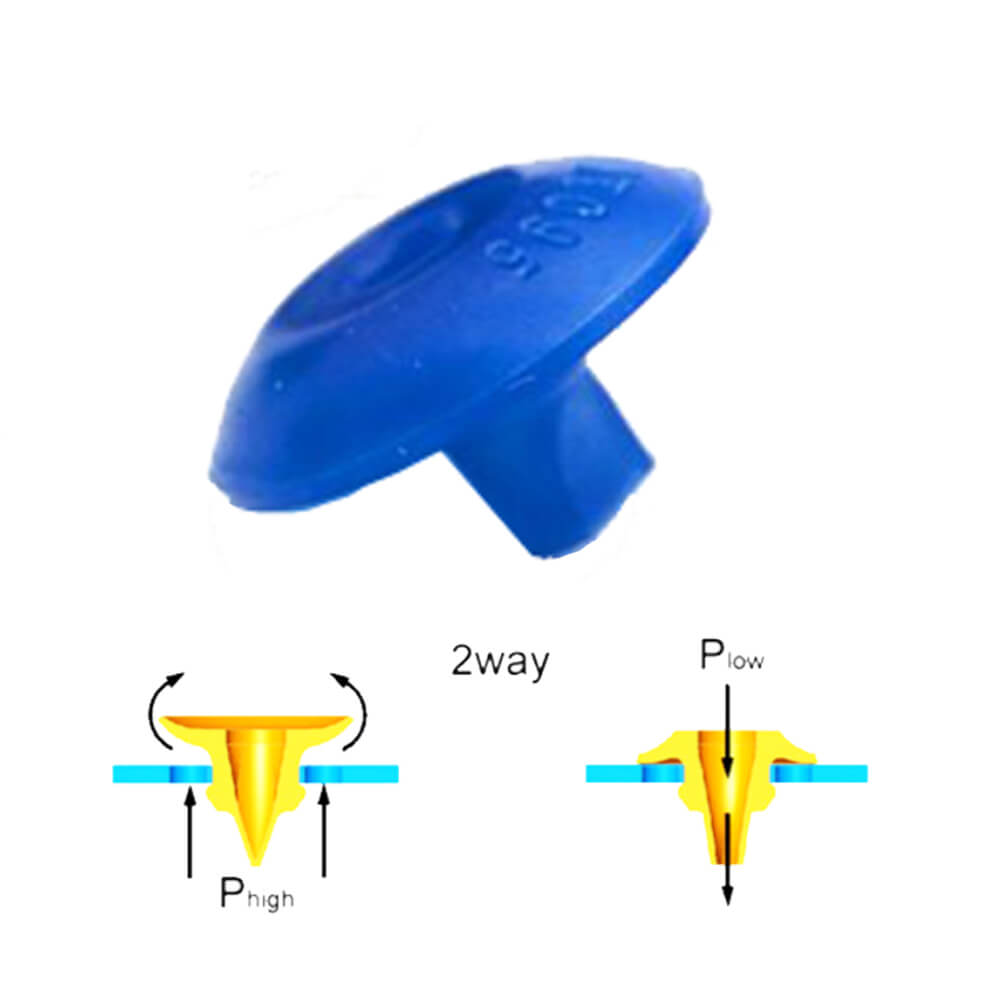

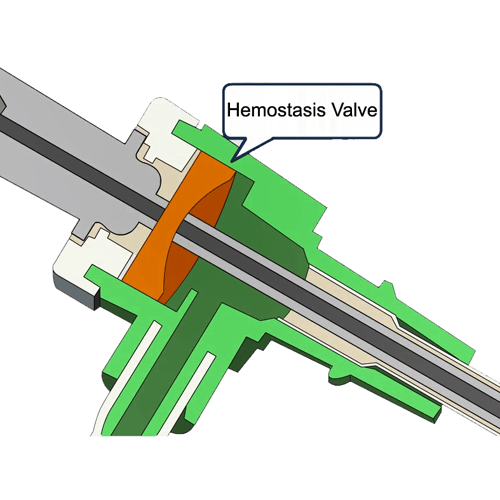

Duckbill Valve, Umbrella Valve, Spring Valve, Diaphragm Valve, Plastic Valve, Silicone Valve, Hemostasis Valve, Dual Valve, Silence Valve, Vacuum Check Valve, Cross Slit Valve etc .

Company Tour

- ① R & D Department — 5 Engineers; ② Mould Department — 11 Engineers

- ③ Quality Department — 6 Engineers;④ Sales Department — 8 Sales Engineers

- ⑤ Production Department — 40 Workers;⑥ 10,000 & 100,000 Cleanroom Workshop

- ⑦ JTSEIKO Labratoray

- Respond time ≤24hours! Online meeting with engineer or sales for valve selection!

Welcome To JTSEIKO

Best Valve supplier That You Can Trust

Over hundreds of types for selection of Valve!

Bio-compatible, Food Grade, Rohs, Reach, Pahs Certifications for Material.

Material Selection of Chemical,Oil,Medicine,Acid,Alkaline,Ozone, Gas Resistent.

Air & Liquid flow test data. Aging, lifetime, chemical resistent test data by JTSEIKO’s Lab.

With designers, engineers, mould workshop to provide OEM & ODM service.

100% Production Inspection, 0 complains with millions of valve using.

Existing products (such as duckbill valves, umbrella valves, silicone valves, valve components, diaphragms, etc.) and services are mainly used in the automotive, medical, small engine, electrical water treatment, food and packaging industries.

Our Products

Quality Guarantee by 100% inspection

Duckbill Valve, Umbrella Valve, Spring Valve, Diaphragm Valve, Plastic Valve, Silicone Valve.

Please Click Photos to Know More

Why Choose Us

OEM & ODM project

Our service includes design, research & innovation, mould process, lab test, mass production and quality control etc.

Product Design

1, Professional designer for ODM work with 20 years' experience.

2, Review with customers together to meet market's request.

Mould & Product Process

1, CNC, Sodick EMD Machine, CMM of Serein to gurantee mould size.

2, Mould review with customer's engineer together to make sure details.

Labratory & Quality Control

1, Quality control by ISO9001 standards with first article inspection, patrol inspection every 2 hours, OQC, IQC, PPAP standards etc.

2, Lab test includes air/water flow, aging, chemical/UV/high & low tempreture resistent, vibration, tensile, etc.

Mass Production

1, 100% test for every product.

2, Automatic assembling and testing is widely used.

What Client Says

Inquiry Now

Make An appointment

Respond Time ≤24hours!

Online Meeting Appointment

Valve Selecting Suggest

Urgent Contact

Contact Information

+86 183 5916 3977

70# Rujiang Road, Mawei District, Fuzhou, China

Lastest News & Knowledge

Videos of test, production, mould, materials, news are published. If you need more data or knowledge please click button below.

How Often To Change Duckbill Valves

This is an article about lifetime. There are factors as following: Let’s list some info as following: Material Durability. The materials quality can affect its

Are duckbill valves dishwasher safe?

Surely Duckbill Valve’s safely using in dishwasher. Duckbill valves are commonly used in various applications, including medical devices, automotive systems, and industrial equipment, etc. So

Are duckbill valves supposed to have gaps?

If you want a high performance of non return function, then A good duckbill valve aren’t suppose to have gaps. Let’s take take a look