How Often To Change Duckbill Valves

This is an article about lifetime. There are factors as following: Let’s list some info as following: Material Durability. The materials quality can affect its

WE ARE PROFESSIONAL CHECK VALVE MANUFACTURER!

This is an article about lifetime. There are factors as following: Let’s list some info as following: Material Durability. The materials quality can affect its

Surely Duckbill Valve’s safely using in dishwasher. Duckbill valves are commonly used in various applications, including medical devices, automotive systems, and industrial equipment, etc. So

If you want a high performance of non return function, then A good duckbill valve aren’t suppose to have gaps. Let’s take take a look

Duckbill Valve’s lifetime counting on several factors, such as material, the conditions it’s exposed to, the frequency of use, temperature, pressure. So lifetime would be

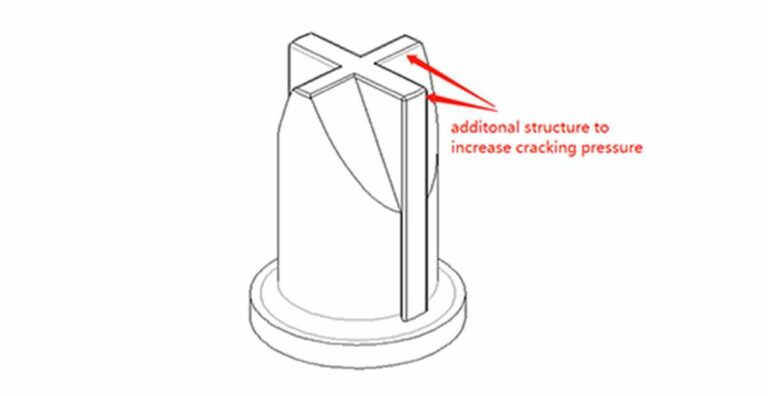

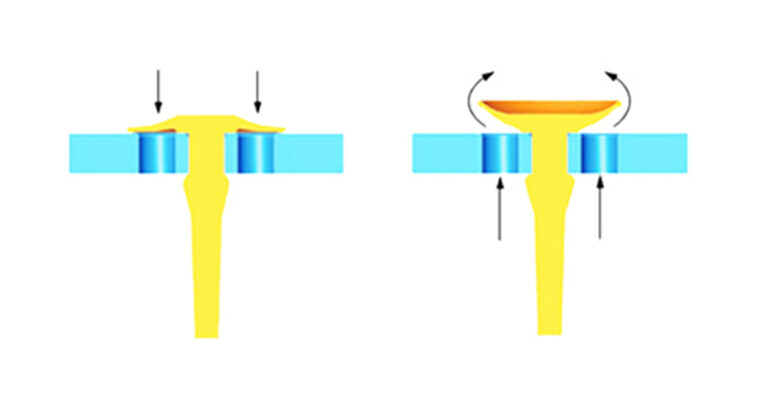

Pressure in duckbill valve includes cracking pressure & back pressure. The small duckbill valve cracking pressure usually is between 0-5Kpa(0-0.71psi). In some situation, you could

When you select mini valves between duckbill & umbrella valves, the biggest differences are fluid type, flow rate, opening pressure setting, back pressure. 1, Fluid

Both duckbill valve and check valve are types of check valves, they are used to regulate the flow of fluids, typically liquids or gases, into one direction and prevent back flow

First of all, why is it called a duckbill valve. By comparing the following two pictures, the shape of the valve body is very similar

Medical Polymer Association, Forum Meeting in Weihai City

Data of air/liquid flow, aging, high & low tempreture, chemical resistent test etc.