Connectors

①Straight & Y & T & Elbow & Cross Connectors

②Barb Size: 3/32″, 1/8″, 1/4″, 3/8″, 1/2″, 1/16″, 3/4″ etc.

③Material: PP, Nylon, PC, etc.

Best Valve supplier That You Can Trust

1、Class 10,000 & 100,000 cleanroom workshops.

2、ISO9001 management system. 100% Inspection. 0 complains with millions of valve using.

3、Rohs, Reach, Food grade and Bio-compatibility Reports.

4、Silicone、EPDM、FKM etc to sellect.

5、Air & Liquid flow test data. Aging, lifetime, chemical resistent test data by JTSEIKO’s Lab.

6、With designers, engineers, mould workshop to provide OEM & ODM service.

Product introduction and features

Model

picture

specification

size

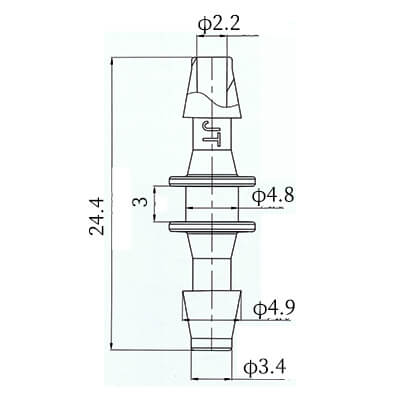

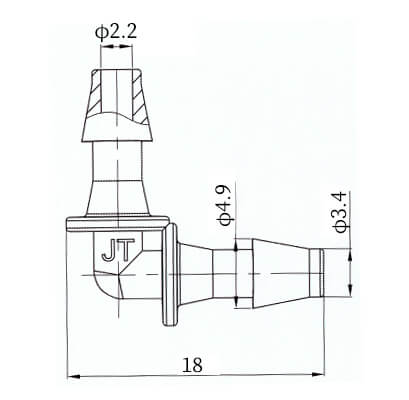

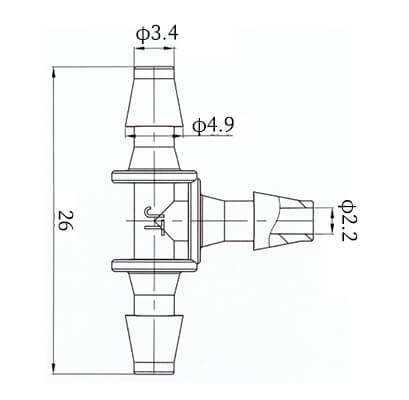

MJT2173

ID:2.2mm

OD:3.4mm

BARB:4.9mm

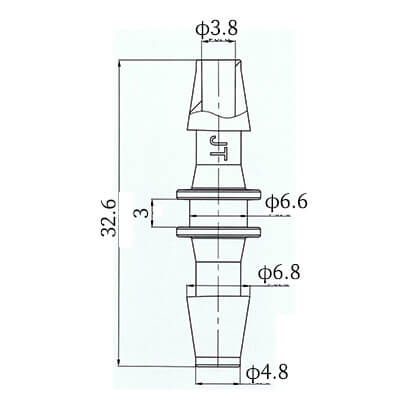

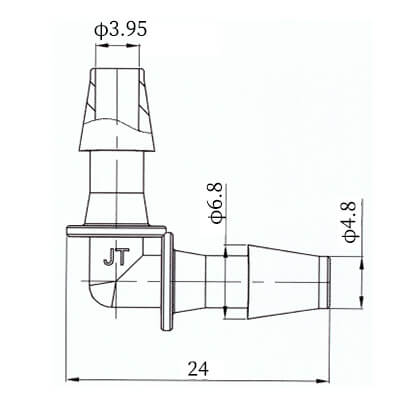

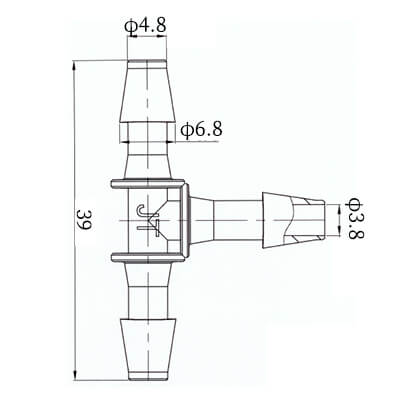

MJT2175

ID:3.8mm

OD:4.8mm

BARB:6.8mm

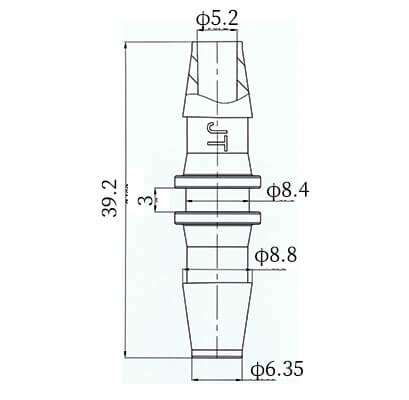

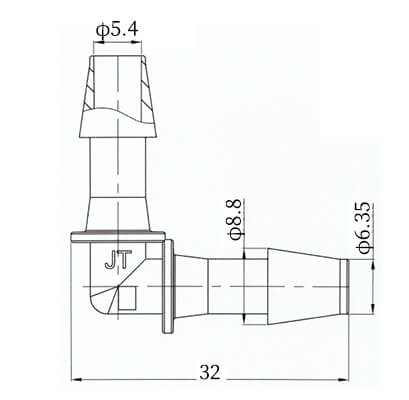

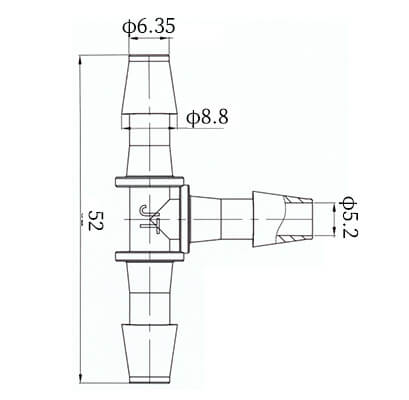

MJT2176

ID:5.2mm

OD:6.35mm

BARB:8.8mm

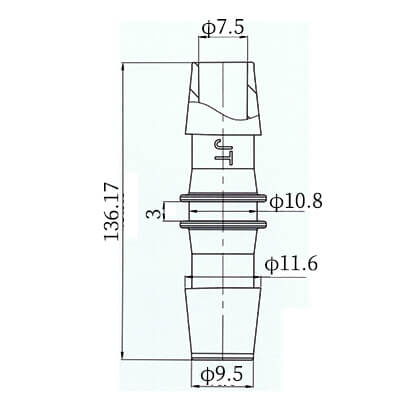

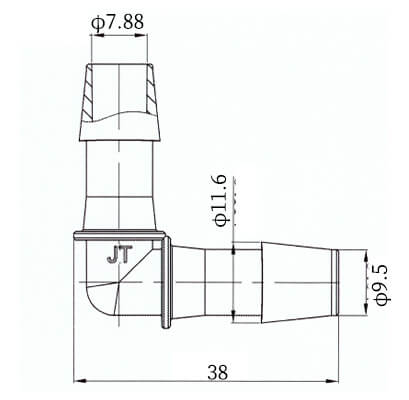

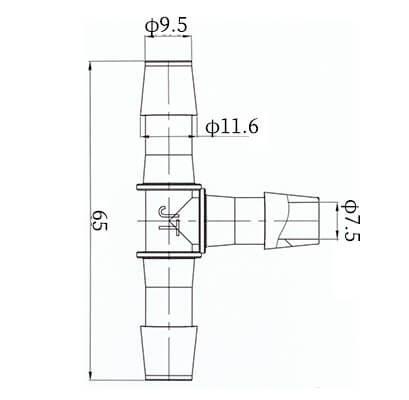

MJT2177

ID:7.5mm

OD:9.5mm

BARB:11.6mm

MJT2178

ID:2.2mm

OD:3.4mm

BARB:4.9mm

MJT2180

ID:3.95mm

OD:4.8mm

BARB:6.8mm

MJT2181

ID:5.4mm

OD:6.35mm

BARB:8.8mm

MJT2182

ID:7.88mm

OD:9.5mm

BARB:11.6mm

MJT2183

ID:2.2mm

OD:3.4mm

BARB:4.9mm

MJT2185

ID:3.8mm

OD:4.8mm

BARB:6.8mm

MJT2186

ID:5.2mm

OD:6.35mm

BARB:8.8mm

MJT2187

ID:7.5mm

OD:9.5mm

BARB:11.6mm

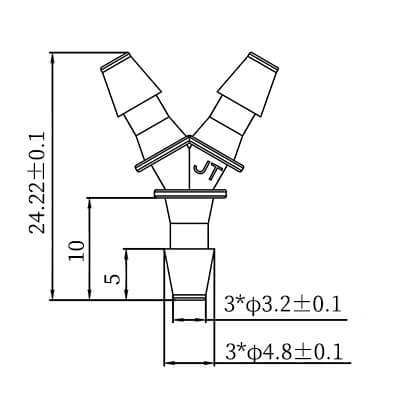

MJT2188

ID:3.2mm

OD:4.8mm

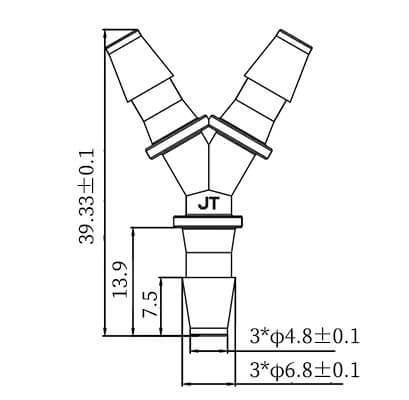

MJT2189

ID:4.8mm

OD:6.8mm

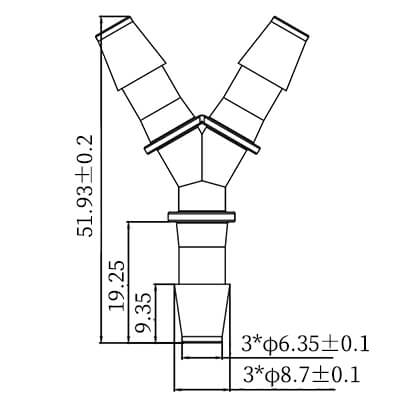

MJT2190

ID:6.35mm

OD:8.7mm

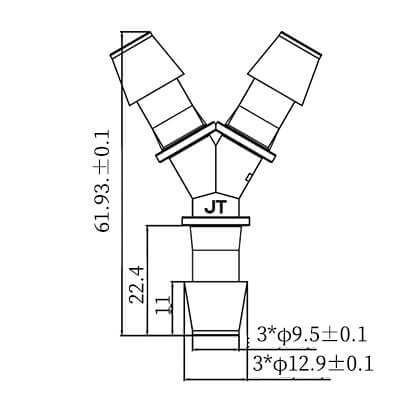

MJT2191

ID:9.5mm

OD:12.9mm

Note:OEM & ODM services provided.

Why Choose Us

OEM & ODM project

Our service includes design, research & innovation, mould process, lab test, mass production and quality control etc.

Product Design

1, Professional designer for ODM work with 20 years' experience.

2, Review with customers together to meet market's request.

Mould & Product Process

1, CNC, Sodick EMD Machine, CMM of Serein to gurantee mould size.

2, Mould review with customer's engineer together to make sure details.

Labratory & Quality Control

1, Quality control by ISO9001 standards with first article inspection, patrol inspection every 2 hours, OQC, IQC, PPAP standards etc.

2, Lab test includes air/water flow, aging, chemical/UV/high & low tempreture resistent, vibration, tensile, etc.

Mass Production

1, 100% test for every product.

2, Automatic assembling and testing is widely used.

plastic materials Selection

Item

Plastic Material Specification

PC

1. Medical Using Mostly, with Bio-compatible Reports

Nylon66(PA66)

1.Tempreture durance from -40℃ to 120℃.

2.Good chemical & weather resistant.

3.Weakness:Absorb water .

ABS

1.Tempreture durance from -40℃ to 80℃.

2.Excellent dimensional stability.

3.Weakness: chemical & weather resistant.

PP

1.Tempreture durance from 0℃ to 80℃.

2.Good chemical resistant.

3.Weakness: poor weather resistant and low tempreture.

PVDF

1.Tempreture durance from -40℃ to 150℃.

2.Excellent chemical resistant.

3.Weakness: expensive.

Note: Contact our engineer to learn more about materials’ info, such as PVC, PE, PC, PMMA,POM, TPU etc.

Plant environment