This is an article about lifetime. There are factors as following:

- Material Durability

- Operating Conditions

- Fluid Compatibility.

- Frequency of Use

- Pressure and Flow.

Let’s list some info as following:

Material Durability.

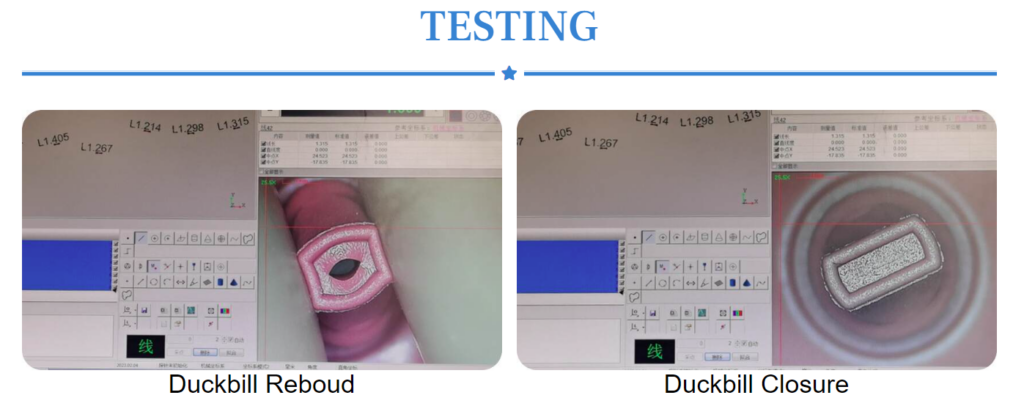

The materials quality can affect its lifetime greatly. Selecting material supplier from Wacker, Dow Corning, Shinetsu or others and evaluate material from beginning is very important. A better material would provide better function, such as duckbill’s rebound.

Operating Conditions

It depends on what function of valve is and circumstance. For example, valve is exposed to extreme temperatures, abrasive fluids, or corrosive chemicals, it may wear out faster.

Fluid Compatibility.

Ensure duckbill valve is compatible with the fluids. Exposure to fluids that are not compatible with the valve material can lead to premature failure.

The photo below is a test that we dip duckbill valve in a oil can and start a vibration test.

Regarding point of Frequency of Use, Pressure and Flow, contact us to know more details of duckbill valve, such as flow data, chemical resistant, material report, ect .

Our Email [email protected] ,

Phone/Whatsapp: +86 18359163977.

Website: www.rubbervalve.com

Or you could learn more about duckbill valve.

And you could follow our social media to learn more about valve’s information, thanks.

Facebook: https://www.facebook.com/rubbervalve/

Linkedin: https://www.linkedin.com/in/rubbervalve/

Youtube: https://www.youtube.com/@rubbervalve120

Twitter: https://twitter.com/rubber_valve